How Are Tyres Made?

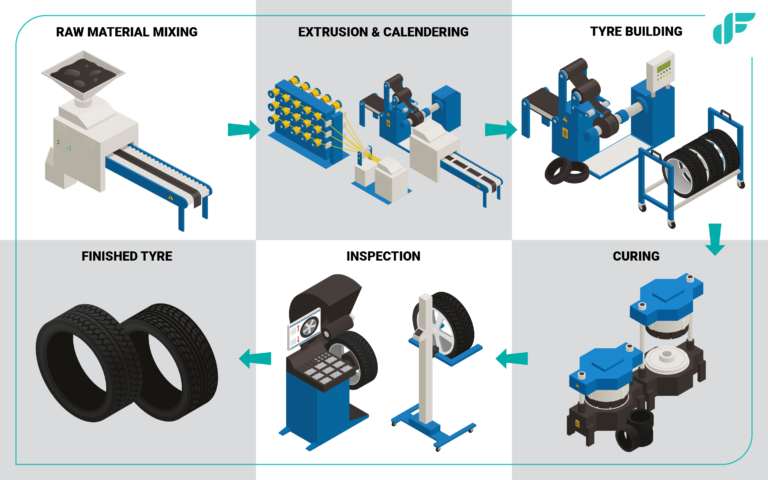

Tyre manufacturing is a complex process that requires precise coordination and careful handling of materials to ensure high quality, safety, and efficiency. In this context, efficient intralogistics, which are the management of material flow, storage, and movement within the factory, plays a critical role in supporting smooth operations. This case study examines the tyre manufacturing process (refer Figure 1) and highlights the importance of optimized intralogistics in enabling seamless material handling and workflow within the facility.

The manufacturing process begins with raw material mixing, where natural and synthetic rubber are combined with chemicals such as carbon black, oils, and curing agents to form specific rubber compounds. Each compound is formulated according to its intended application within the tyre to ensure the required physical properties and consistency. Once the mixing process is completed, the prepared rubber compounds are transferred to the next production line for component forming.

The rubber compounds then undergo extrusion and calendering to form the various components of the tyre. Extrusion is used to produce parts such as treads and sidewalls, while calendering coats fabric and steel cords with rubber to create belts, plies, and beads. These components provide the tyre with its structural strength and flexibility. After forming, each tyre component is systematically transferred to the next production line for assembly.

During tyre building, all individual components are assembled in a specific sequence to form a green tyre. This process requires precise placement of fabric plies, steel belts, beads, and tread to ensure uniformity and structural integrity. At this stage, the tyre has its complete shape but has not yet been hardened. Once the green tyre is built, it is transferred to the next production line for curing.

Curing involves placing the green tyre into a mould and subjecting it to controlled heat and pressure. This process vulcanizes the rubber, permanently bonding the components together and forming the tyre’s final tread pattern and mechanical properties. After curing is completed, the finished tyre is transferred to the next production line for inspection.

Following curing, each tyre undergoes inspection to verify that it meets the required quality and safety standards. This includes visual inspections, dimensional measurements, and testing for defects or irregularities. Tyres that pass inspection are then transferred to the final stage for storage and outbound handling.

Approved finished tyres are moved into the warehouse, where they are stored in an organized manner to support efficient retrieval and distribution. From there, tyres are prepared for outbound logistics and dispatched to customers, distributors, or vehicle manufacturers.

*This case study outlines the primary stages of the tyre manufacturing process, while other supporting and additional processes within the facility are not included such as bead manufacturing, belt steel cord manufacturing and fabric ply cutting.

Problem Statement

In tyre manufacturing facilities, material handling plays a critical role in maintaining production continuity, safety, and operational stability. When intralogistics operations rely heavily on manual handling and conventional forklifts, multiple inefficiencies arise across the production floor.

Safety risks are a major concern, particularly in shared zones where forklifts operate alongside production personnel. Limited visibility, operator-dependent driving behaviour, and the absence of standardized material transfer routes increase the likelihood of near-miss incidents and workplace injuries. These conditions make safety performance highly reliant on individual judgement rather than a controlled system.

Inconsistent material flow further impacts production performance. Delays in transferring raw materials, tyre components, or green tyres often caused by forklift availability constraints or task prioritization conflicts disrupt just-in-time operations. This results in line stoppages, uneven material supply, and unbalanced production flow.

Heavy dependence on manual handling also introduces high process variability. Differences in operator performance and shift execution lead to inconsistent delivery timing, staging accuracy, and material availability, making it difficult to standardize operations or optimize production planning. In addition, unstructured material staging and forklift parking contribute to floor congestion, reducing space efficiency and increasing safety risks.

Labour dependency and limited material traceability further compound these challenges. Reliance on skilled operators exposes intralogistics operations to workforce fluctuations, while reduced visibility of material movement increases the risk of misrouting, damage, and quality inconsistencies particularly for sensitive materials such as rubber compounds and green tyres.

Solution

To tackle material handling and intralogistics challenges in tyre manufacturing, Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) automate the transport of raw materials, components, and semi-finished tyres across the production floor. By automating material handling, these systems ensure consistent and reliable transfers, reducing consequences caused by manual handling.

Automation also reduces process variability by delivering materials according to predefined schedules and routes. This ensures that each production line receives the right materials at the right time, supporting just-in-time manufacturing and minimizing line stoppages. In addition, automated systems enhance workplace safety by reducing human interaction with heavy loads and separating pedestrian zones from material transfer routes, lowering the risk of accidents in high-traffic areas.

Another key benefit is improved material traceability. With integrated sensors, RFID, or barcode tracking, AMRs and AGVs provide real-time visibility of material location and movement. This ensures accurate work-in-progress monitoring, reduces misplacement or misrouting, and allows better planning and inventory control.

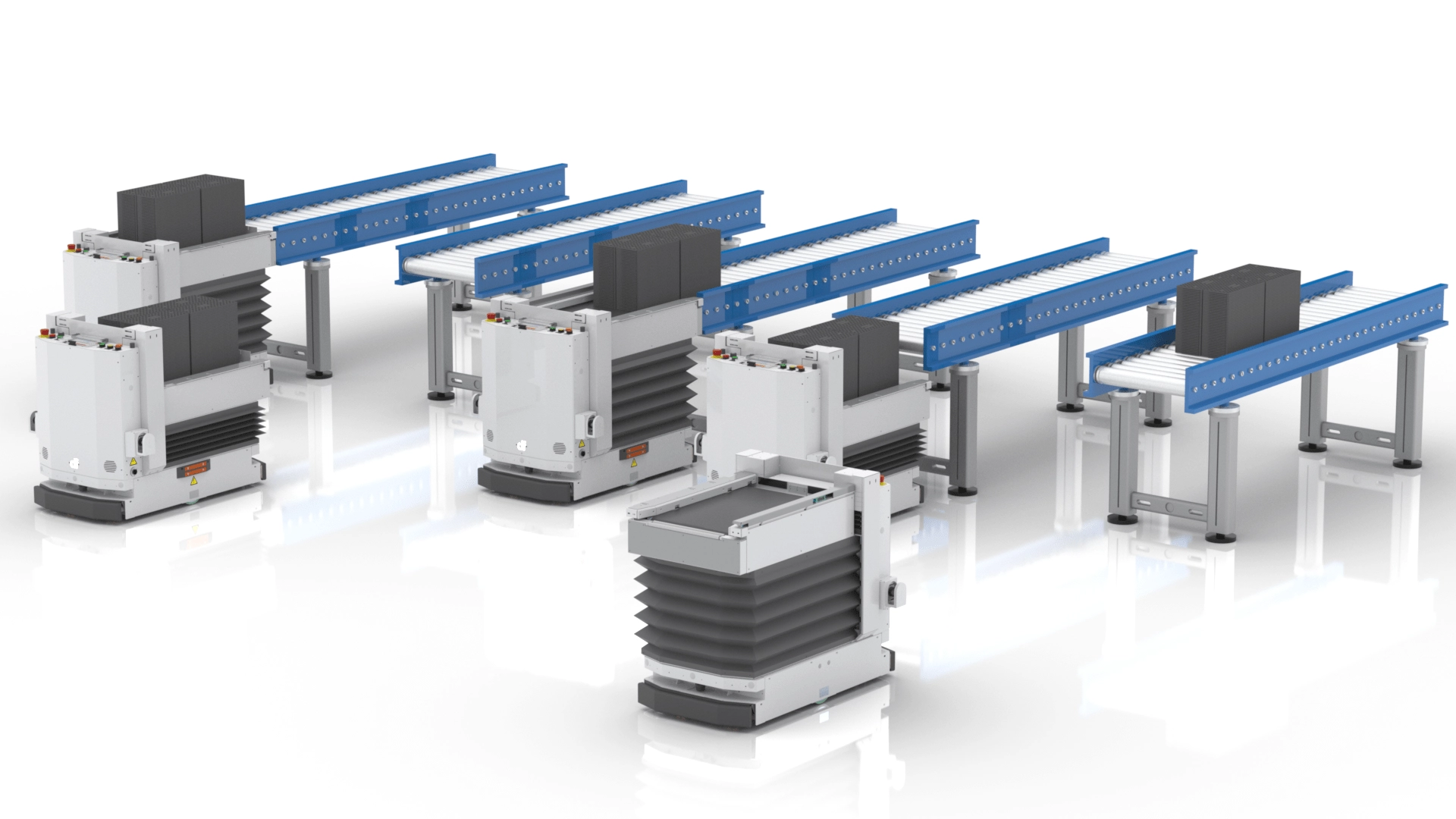

Two examples of automation solutions that can be implemented in tyre manufacturing from DF Automation & Robotics include:

1. Zetha AMR – A pallet transfer AMR capable of carrying up to 2 tonnes. It is ideal for transferring heavy pallets of raw materials or components between production areas, ensuring smooth flow without manual intervention. Refer Figure 2 for Zetha AMR

Actual Case of Zetha AMR in a Tyre Manufacturing Facility:

Zetha AMR was successfully deployed in a tyre manufacturing facility to handle ultra-heavy components safely and efficiently. In this application, it moves cassettes containing tyre components and raw materials weighing up to 1,250 kilograms between two production locations. The system completes approximately 80 tasks per day, covering an average distance of 19 kilometers at a speed of around 1 meter per second. This deployment demonstrates how Zetha AMR can optimize intralogistics, reduce manual labor, and ensure consistent, safe material handling in a demanding manufacturing environment.

2. Zamma – An autonomous forklift with a lifting height of up to 3 metres. Zamma can handle pallet racking tasks or deliver materials directly into machines at higher elevations, enabling flexible and efficient operations in areas that require vertical handling. Refer Figure 3 for Zamma TS Standard L16 model.

Potential Application in Tyre Manufacturing Facility:

Zamma can be implemented in tyre manufacturing facilities to support material handling in challenging environments. With a lifting height of up to 2.4 m and a load capacity of 1.2 – 2.0 tonnes, it can autonomously transport raw materials and components to elevated locations, such as mixers and processing stations. Its advanced safety features and autonomous operation allow it to function effectively in areas with high temperatures and strong chemical odors, typical of rubber mixing and compound preparation zones. By reducing manual handling in these demanding conditions, Zamma can improve efficiency, safety, and workflow reliability in the tyre manufacturing process.

By integrating these automation solutions, tyre manufacturing facilities can achieve a more efficient, safe, and reliable intralogistics system. Automation reduces reliance on manual handling, streamlines material flow, enhances operational consistency, and improves overall visibility across the production process. This ultimately supports higher productivity, better quality control, a more resilient manufacturing environment, and a strong return on investment through optimized operations.

Want to learn more? Submit your inquiry via our Contact Form, and our team will get in touch to assist you.

Author: Shree Jadhav l Dr Yeong Che Fai

Editor: Shalani Krishnan

DF Automation & Robotics is one of the leading robotics companies in Southeast Asia, specializing in the design and manufacture of Autonomous Mobile Robots (AMRs) for the global automation and robotics industry. The company’s success is driven by its two proprietary AMR software solutions – NavWiz and DFleet – which are utilized across multiple industries. NavWiz serves as the cognitive engine for the robots, enabling seamless autonomous navigation, while DFleet facilitates efficient fleet management and optimizes traffic control in factory environments.

With over 500 robots deployed worldwide, DF Automation & Robotics has successfully expanded its solutions to countries such as Malaysia, Singapore, Thailand, India, Mexico, and various European nations. Visit www.dfautomation.com to learn more.